Key Considerations When Choosing Industrial Scales for Your Warehouse Operations

Key Considerations When Choosing Industrial Scales for Your Warehouse Operations

Blog Article

Why to Pick Industrial Scales for Accurate Weight Measurement in Numerous Industries

In an era where accuracy is paramount, the choice of industrial scales for precise weight measurement plays a crucial role across diverse fields. These scales not only improve operational effectiveness but likewise make certain conformity with governing criteria, affecting everything from production to delivery. Their durable design and advanced technology deal with various applications, reinforcing the requirement for precise weight management. Recognizing the nuances of these scales is essential for any type of company intending to enhance procedures and reduce costly errors. Yet, the concern continues to be: what specific elements should one take into consideration when picking the right scale for their one-of-a-kind functional demands?

Significance of Accurate Weight Dimension

In the world of commercial procedures, the relevance of precise weight measurement can not be overstated. Accurate weight dimension is fundamental throughout various markets, influencing both operational efficiency and product high quality - Industrial Scales. It acts as a crucial aspect in stock monitoring, making certain that materials are effectively made up, thus decreasing waste and minimizing expenses

In production, precise weight dimension straight influences manufacturing processes. Abnormalities in weight can bring about low-grade items or extreme source allowance, influencing total success. Furthermore, in markets such as pharmaceuticals and food manufacturing, adherence to stringent weight specifications is essential for regulative conformity and consumer security.

Furthermore, exact weight measurements assist in reliable logistics and supply chain administration. Properly weighed deliveries ensure that transportation prices are maximized and that supply levels are preserved properly, consequently preventing supply scarcities or overstock situations.

Types of Industrial Scales

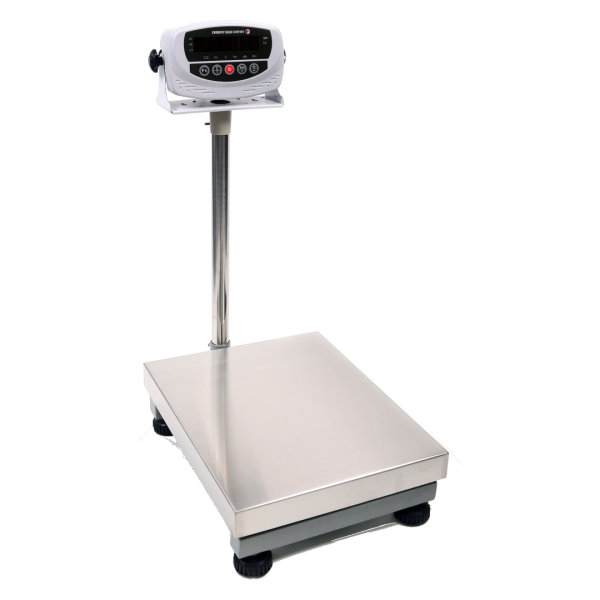

A wide array of commercial scales are offered, each developed to fulfill particular dimension requires throughout varied sectors. Common kinds include flooring scales, which are robust and suitable for weighing large items or pallets in warehouses and distribution facilities. Bench scales are smaller sized and optimal for lighter products, typically used in retail setups or manufacturing for specific section control.

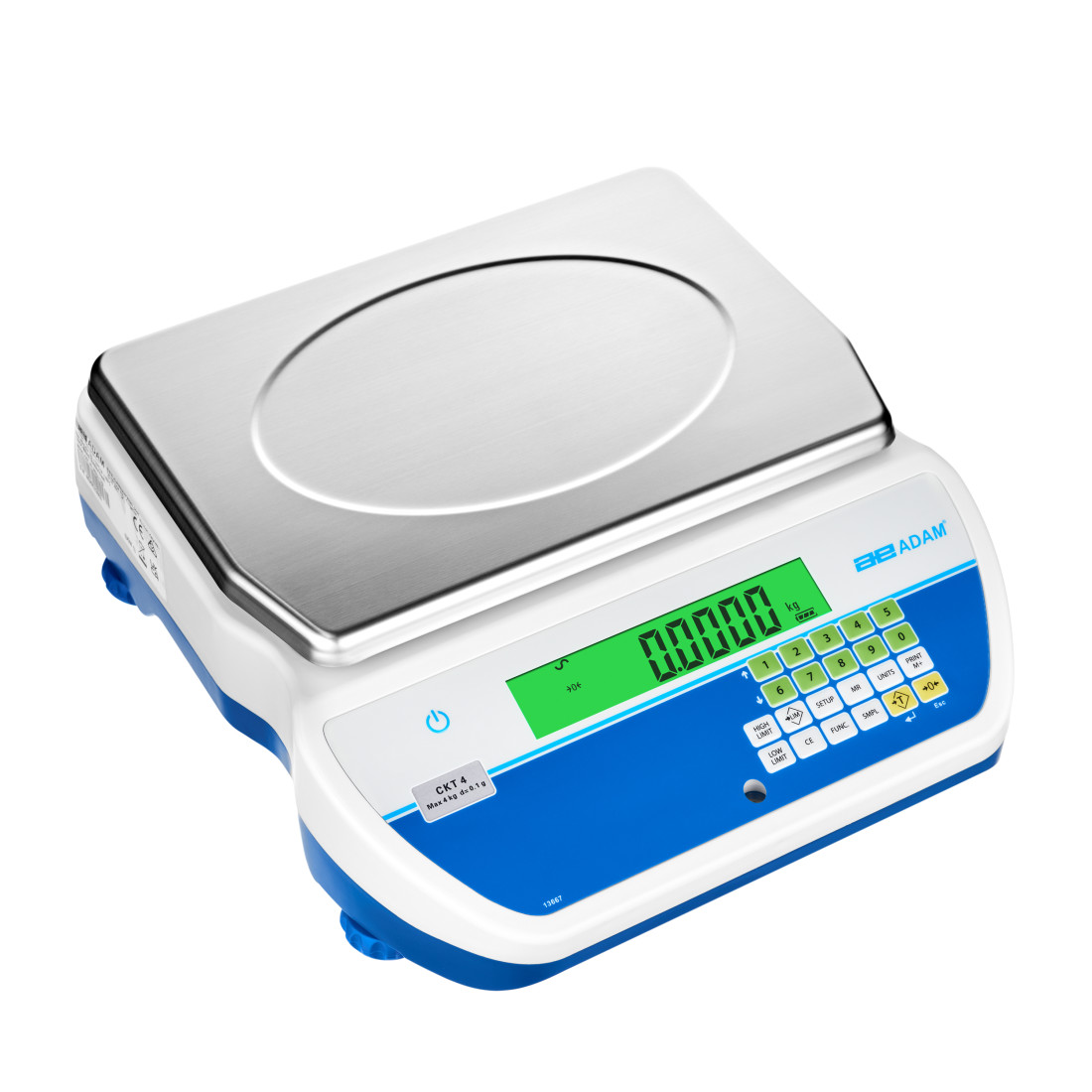

An additional category is portable ranges, which provide the flexibility to be relocated conveniently around task websites, making them ideal for field operations or short-term setups. Precision ranges, on the various other hand, are designed for high accuracy and are often used in research laboratories and high quality control atmospheres.

Tons cells are essential parts in different commercial scales, converting push into an electric signal for accurate analyses. Furthermore, vehicle scales give the methods to weigh heavy cars and their tons, ensuring compliance with guidelines and maximizing logistics.

Last but not least, checkweighers instantly compare the weight of items against preset limitations, improving quality assurance in assembly line (Industrial Scales). Each sort of commercial range serves an one-of-a-kind feature, satisfying the particular needs of sectors such as manufacturing, logistics, food handling, and pharmaceuticals

Benefits of Utilizing Industrial Scales

Consistently making use of commercial scales offers considerable benefits across various industries. Among the primary advantages is boosted accuracy in weight dimension, which is vital for keeping quality criteria and regulative compliance. Exact dimensions stop expensive errors in shipping, manufacturing, and inventory administration, ultimately leading to raised operational efficiency.

Additionally, industrial ranges are check my blog developed for toughness and robustness, permitting them to endure harsh atmospheres generally located in manufacturing and warehousing. This strength guarantees a lengthy lifespan, minimizing the need for regular replacements and maintenance prices.

Furthermore, using commercial scales improves security and minimizes waste. By guaranteeing that items are considered properly, companies can stay clear of overloading lorries, which can result in penalties and accidents.

Applications Across Various Industries

Industrial scales play an essential function in various industries, consisting of manufacturing, logistics, food handling, and drugs. In manufacturing, these scales are important for ensuring that raw materials are gauged properly, therefore keeping product quality and uniformity (Industrial Scales). Accuracy in weight measurement straight affects manufacturing performance and expense management

In logistics, commercial scales facilitate the exact evaluating of shipments, which is crucial for sticking to optimizing and delivering regulations products costs. Exact weight data aids simplify operations and boosts supply chain administration.

The food handling market relies greatly on industrial ranges for compliance with health and wellness guidelines. They are used to consider components exactly, guaranteeing that solutions meet both top quality standards and lawful requirements. This is vital not just for consumer security yet likewise for preserving brand name integrity.

Drug firms utilize commercial ranges to guarantee precise does in drug production, where also the slightest variance can have substantial consequences. Compliance with rigorous regulatory requirements makes precise weight measurement essential in this industry.

## Variables to Take Into Consideration When Picking Ranges

Choosing the right range for particular applications needs cautious consideration of several aspects. The capacity of the scale is important; it needs to fit the optimum weight of the products being determined without surpassing its limitations. Furthermore, the readability, or tiniest increment the range can precisely present, try this site is vital for accuracy, specifically in sectors where weight disparities can lead to substantial economic losses or safety and security problems.

Environmental conditions additionally play a substantial function in scale selection. Scales used in corrosive or humid environments might need specialized products to guarantee resilience. Similarly, check my reference transportability may be necessary in certain applications, requiring battery-operated and light-weight models.

Conclusion

Finally, the option of industrial scales is critical for making sure exact weight dimension across varied markets. Their capacity to give accurate readings not only enhances operational efficiency yet likewise sustains governing conformity and inventory monitoring. The adaptability and resilience of these scales facilitate their application in numerous industries, inevitably adding to cost decrease and boosted item high quality. Thus, purchasing top notch industrial ranges is important for organizations aiming to preserve high requirements and optimize productivity.

Report this page